U.S. lead battery recyclers are critical to a circular economy and sustainable energy storage, preventing more than 160 million lead batteries from reaching landfills each year. To accomplish this, our employees do important work in sometimes demanding environments in these crucial recycling facilities.

Rigorous, ongoing safety training programs give employees the knowledge, skills and awareness necessary to ensure their own safety in the workplace, as well as the safety of others.

Average safety training per operations employee each year.

Our members invest significant capital to ensure their operations meet and exceed the highest environmental, health and safety regulatory standards in the industry.

70M

Average investment in EHS

improvements between 2010-2020.

30%

Average EHS allocation by lead

battery recyclers.

10%

Average percentage of on-site staff

working in EHS related positions.

U.S. battery recyclers provided workers with the necessary personal protective equipment (PPE) to safeguard them according to their work area.

Click on a number to learn more

1

Hard hats protect from impact and other injuries.

2

Safety glasses, goggles or face shields protect the eyes and face from debris and other hazards.

3

Job-appropriate respirators protect against potentially harmful particles and gases.

4

Ear plugs and earmuffs protect hearing and minimize the stress of noisy work environments.

5

Body coveralls, acid and flame proof aprons, and cooling vests protect from head and hazardous materials. Uniforms worn and laundered by the recyclers provide whole-family protection.

6

The right gloves for the job protect against cuts, scrapes and burns.

7

Suitable footwear, such as boots, foot guards or safety shoes.

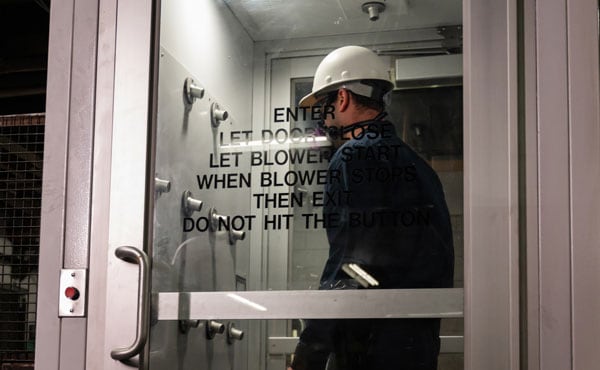

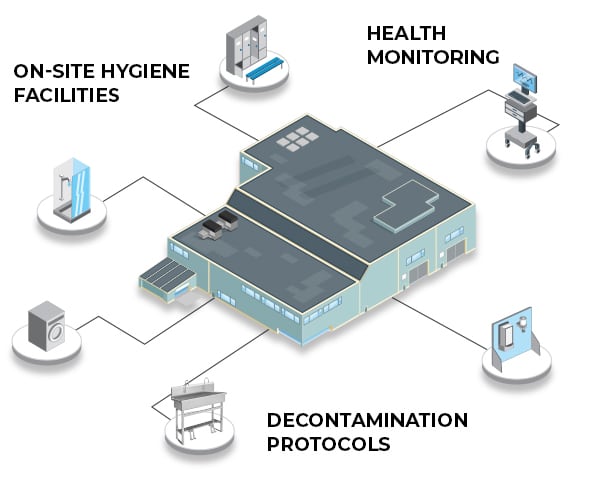

The lead battery recycling industry has adopted voluntary measures that often exceed OSHA standards for our industry and provide better protection for workers. Employees are trained regularly and empowered to adhere to stringent health and hygiene protocols to protect themselves, each other and their families.

Clean and dirty locker rooms, showers and laundry services minimize the potential for lead to leave the workplace.

Plant workers participate in regular health monitoring, including initial employment physicals, blood-lead level monitoring and ongoing testing.

The use of body vacuums, handwash stations and lead-check stations help detect and prevent lead dust from leaving the facilities.

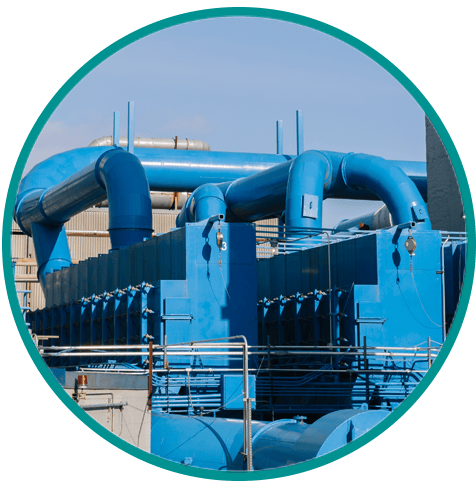

Our member companies understand that cleaning the air is crucial to a healthy workplace. Lead battery recycling facilities rely on the extensive use of industrial ventilation and air filtration solutions to draw dust and fumes away from workers and to help protect the environment.

ABR member companies are committed to prioritizing the health, safety and wellbeing of our employees, their families and the communities in which we live and work. We do so through significant investment and ongoing education in environmental, health and safety best practices.