ABR’s Spring Meeting Brings Industry Leaders Together

Representatives from ABR’s member companies recently came together for our annual Spring Meeting. As part of our industry commitment to empowering responsible recycling, we host in-person conferences to foster collaboration and sharing of ideas, best practices and the latest innovations.

Continuous Investment in Safety and Air Quality

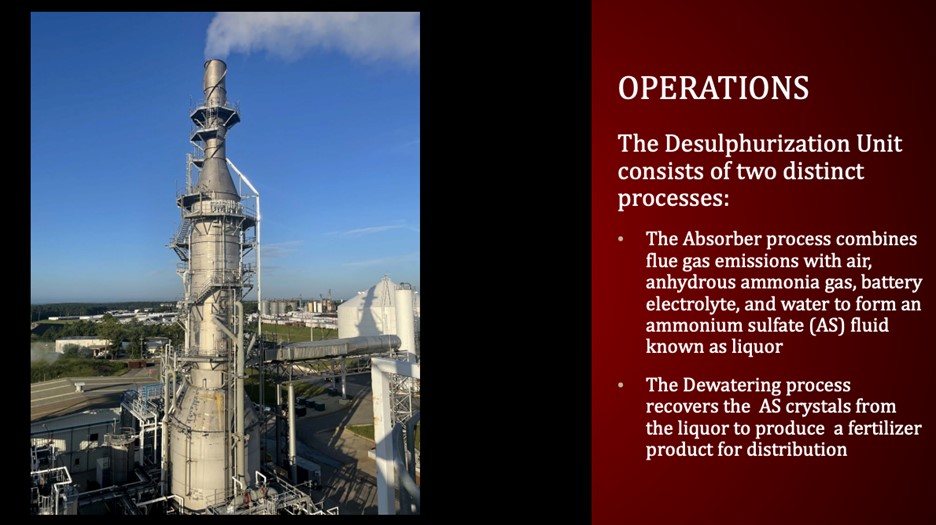

This year, the focus was on employee safety and innovative technology to help protect the environment. Jeramy LeMieux, Vice President of EHS at Clarios, spoke about the Clarios blood lead level reduction program. Chris Rutherford, Manager of Environmental Services at Sanders/KW Plastics, talked about new equipment they’ve recently installed to desulphurize flue gas.

Using Data to Help Lower Blood Lead Levels

At Clarios, Jeramy LeMieux is using insights drawn from new ways of looking at employee data to reduce blood lead levels across all locations. “Our focus is to utilize proven solutions, data, and analytics to continuously drive progress,” said LeMieux. In his presentation, he detailed how he analyzed data to find a way to decrease blood lead levels beyond what was previously thought possible, starting with answers to the questions of why some employees and some locations experienced higher blood lead levels. Giving employees enough time and a space where they are comfortable to use the proper hygiene turned out to be key. “If you make a commitment to your workforce and put these fundamentals in place, it will be easier to promote hygiene,” said LeMieux.